SERVICES

Ballbar Testing

Ballbar Analysis services will improve the performance of your machine tool, increase your product quality, and expand your bottom line. Renishaw ballbar testing provides a quick and powerful assessment of a machine's performance to identify areas where remedial action may be required.

Leveling & Alignment

Machine leveling is a broad term used in the machine tool industry during machine installation of machine tables, rails, and the base. While it is critical in some applications that the machine base, rails, and tables are level, it is more important that machine axes, spindle, and the working surfaces have excellent geometric relationships per the machine's intended design.

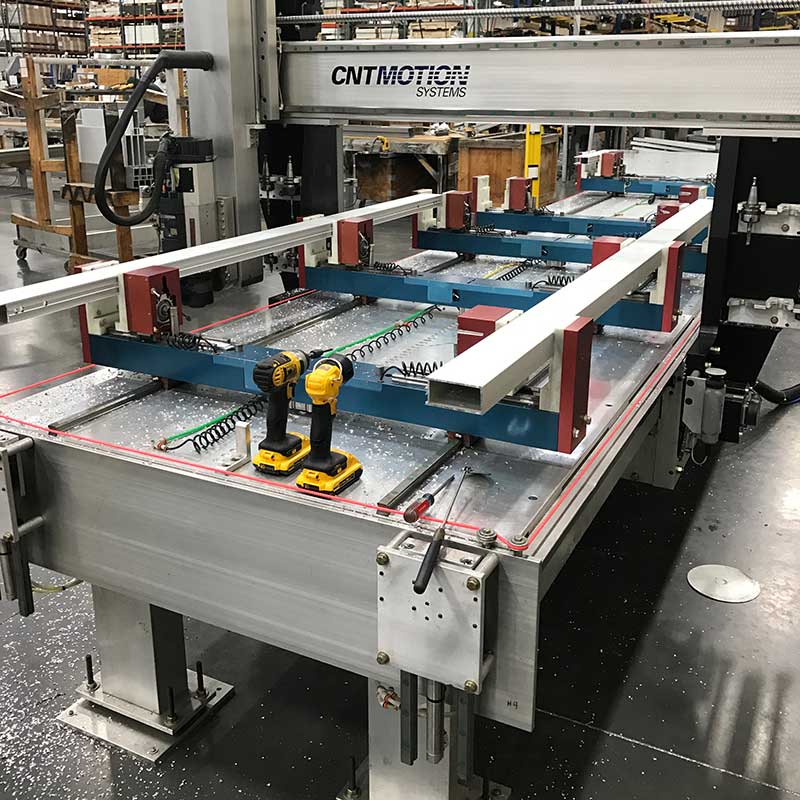

Machine Installation

Texas Express CNC's experienced technicians assist you every step of the way in the efficient and safe installation and start-up of your machine tool. We'll assist in the proper location, placement, leveling, and machine tool alignment. Once installed, our technicians will assure you that your machine will hold tight tolerances, ensure machine reliability, and lengthen the life of your equipment. Ensuring your equipment is installed correctly is also a crucial factor in the safety of your shop and employees.

Onsite CNC Services

We can handle your most critical onsite machine tool problems. Whether your company requires help with troubleshooting CNC controls, checking alignments, or performing preventative maintenance, you can count on Texas Express CNC. Texas Express CNC makes it simple; let us be your one-stop shop for all your machine tool service needs, no matter what the make and model. Some of the brands we service include, but are not limited to:

- Haas

- Yama Seiki

- Vanguard

- Mazak

- Viper

- Ikegai

- Leblond

- Kitamura

- Fadal

- Bridgeport

- TREE

- Omni-Turn

- Dah-Lih

- Nigata

- Femco

- Excell

- Clausing

- Leadwell

- Okuma

- Dae Woo/Doosan

- Kingston (Manual/CNC)

- Toyoda

- Kuraki

- Toshiba

- OKK

- Samsung

- Blanchard

- Whacheon

- Lagunamatic

- Yang

- Mori Seiki

Preventative Maintenance

Texas Express CNC offers a wide range of machine tool services, but there is one that most people tend to overlook - Preventive Maintenance. Aside from minimizing wear and eliminating all emergency breakdowns, a Preventive Maintenance Program provides a permanent record of the machine's maintenance history and its current condition. Planned maintenance allows you to schedule your machine downtime, rather than your machine downtime scheduling you. Studies have proven that a Preventive Maintenance Program creates large savings in machine tool repair costs and increases productivity due to less downtime. Texas Express CNC can customize a Preventive Maintenance Program to fit your exact requirements. Whether you are looking for an annual or semi-annual plan, we can help you design, organize, and execute the entire program.

Rebuilds

Save money and bring your existing machines up to date by having your CNC machines rebuilt by Texas Express CNC. Your equipment will work as good as new. We rebuild to the highest standards. Rebuilding saves you money over buying new, not at the time of rebuild, but down the road maintenance costs are usually lower because you'll have access to interchangeable parts from older machines. Rebuilding a CNC machine allows for the possibility of expanding the machine's capabilities and many times a rebuilt machine is better and more dependable than a comparable new machine, running much more smoothly. Rebuilds include:

- Turcite, scraping and fitting

- Testing and balancing

- Lathe mill spindle repair

- CNC Circuit Boards repair and replacement

- Complete geometric alignment

- Spindle repair and rebuilding

- Revolving tool repair

- Fanuc repair

- CNC troubleshooting

- CNC repair

- Re-calibration

- Overhaul Services

- Servo motor repair

- Ballscrew repair

- Precision Scraping

Scraping Services

Hand scraping is a manual process that requires an individual to use a hand tool called a flat scraper to scrape metal from a machine tool surface to create contact points and oil grooves on surfaces that need to be mated together.

Used Machine Inspection

Used machine inspection will help you ensure that the machine you are buying is in good working condition, before you buy it. It is amazing how many companies neglect to inspect a machine before they buy. We know about the important items to check, including a report on the machine's spindle time, what replacement parts will cost, etc. Once you have paid for a used CNC machine, it's too late. An inspection and report from Texas Express CNC will give you negotiating power and peace of mind.